Fabrikplanung

-

HyFlowJobShop - Hybrid, flow-oriented assembly organisationThe research project HyFlowJobShop aims to combine the organisational forms of flow and workshop principle. The previous pure organisational forms can no longer meet the increased requirements with regard to increasing variant diversity and shorter amortisation times for production systems due to shorter product life cycles. The combination of the workshop and flow principle to form hybrid organisational forms is intended to offer manufacturing companies an opportunity to position themselves in the field of conflict between the required flexibility and the achievement of production logistics targets as well as the resulting costs. To quantify the advantages of hybrid organisational forms, various system configurations are examined as part of a simulation study in order to identify interdependencies and influencing variables.Led by: Dorit Schumann, Marco BleckmannYear: 2022Funding: German Research Foundation (DFG)Duration: 08/2022 – 09/2024

![]()

![]()

-

reQenrol - competence- and quality-based personnel resource planning and training in productionThe reQenrol research project aims to develop both a concept and a software demonstrator for skills- and quality-based workforce scheduling and training in manufacturing SMEs using smart devices. Staff scheduling is to be supported by an intelligent assistance system that provides recommendations for the skills-based allocation of employees to activities. At the same time, the system identifies the necessary training documents and provides them to employees via smart devices in order to close any gaps between actual and target qualifications through efficient on-the-job training. Any increases in skills achieved are systematically recorded and employees' skills profiles are updated accordingly. Enabling SMEs to systematically increase their employee flexibility is of paramount importance.Year: 2021Funding: AiF FQSDuration: 01.08.2021-31.07.2023

![Logo des Forschungsprojektes reQenrol]()

![Logo des Forschungsprojektes reQenrol]()

-

TransferMetroPlant - Development of an application-oriented tool for economic development organizations as an adequate support to companies in the location planning and development within metropolitan regionsThe research project "TransferMetroPlant" focuses on the transfer of knowledge between science, business and the public sector within site planning. The aim of TransferMetroPlant is to develop an application-oriented planning tool for economic developers that will serve to provide demand-oriented support for companies in site planning and development within metropolitan regions.Year: 2021Funding: DFGDuration: 01/2021 – 06/2022

![]()

![]()

-

teamIn - Interactive leadership and technologies for the team interaction of tomorrowThe teamIn research project aims to develop a model for the digitally supported management organization of tomorrow. The focus is on a holistic view of technology in combination with the skills and needs of users. The result is concrete leadership and organizational concepts that incorporate digital methods, such as artificial agents or live employee feedback. These enable future-oriented management and organizational structures and thus improve internal communication. Involving everyone involved in the process of change is of paramount importance.Year: 2020Funding: BMBF, ESF, PTKADuration: 01/2020 - 12/2022

![]()

![]()

-

HaLiMo 2 - Systematische Untersuchung der Wirkung von Verfahren der Produktionsplanung und der Produktionssteuerung auf logistische ZielgrößenZiel des Forschungsprojektes ist zum einen die strukturierte und einheitliche Sammlung von Verfahren zur Erfüllung der Aufgaben im Rahmen der Produktionsplanung und -steuerung. Darauf aufbauend sollen sowohl die direkten als auch die indirekten Wirkungen der PPS-Verfahren auf die logistischen Zielgrößen untersucht werden. Ergebnis dieser Untersuchungen sollen belastbare Aussagen über die Wirkzusammenhänge sein. Die Beschreibung der Wirkzusammenhänge erfolgt hierbei quantitativ durch die mathematische Verknüpfung der Elemente der unternehmensinternen Lieferkette und den logistischen Zielgrößen mithilfe von bestehenden logistischen Modellen.Year: 2020Funding: DFGDuration: 03/2020 - 07/2022

![]()

![]()

-

Transferprojekt - Logistikorientierte Reihenfolgestrategien für mehrstufige ProduktionenZiel des Forschungsprojekts ist es, ein allgemeines Vorgehensmodell zur Bestimmung einer logistikorientierten Reihenfolgestrategie für Produktionsbereiche zu entwickeln. Aufbauend auf Vorarbeiten werden hierfür die Auswirkungen verschiedener Reihenfolgeregeln auf das Terminabweichungsverhalten sowie Produktivitätsgewinne an einzelnen Arbeitssystemen quantitativ bewertet und miteinander verknüpft. Unter Berücksichtigung konfliktärer Zielgrößen und der Diskussion möglicher Kompensationsmaßnahmen erfolgt die Ableitung des Vorgehensmodell, welches bei einem Anwendungspartner implementiert wird.Year: 2019Funding: DFGDuration: 01/2019 - 12/2019

![]()

![]()

-

Capacity planning and quotation costing for transformer regeneration by means of data miningWithin the project D1 of CRC 871 a new approach for capacity planning in terms of the regeneration of aircraft engines was developed. This approach will be enhanced in cooperation with a rail vehicle transformer manufacturer to consider the specific conditions and restrictions. Therefor a process model will be conveyed and different algorithms will be developed to enable capacity planning and load control as well as quotation costing at previously uncertain workload for regenerating rail vehicle transformers.Year: 2019

![]()

![]()

-

WiMo - Development of a model for the quantitative description of logistical cause-effect-relationships for different forms of assembly organization.The aim of the research project is to develop an effect model for the analytical description of logistic targets for multi-stage assembly processes. With the aid of the model to be developed, suitable logistical measures to improve the logistical efficiency of a variety of assembly organisation forms are to be derived and quantitatively evaluated.Year: 2019Funding: DFGDuration: 2017 - 2019

-

I4PE - Industry 4.0 Project Platform for the Introduction for SMEsThe research project "Industry 4.0 - Project Platform for the Introduction of SMEs (I4PE)" aims to develop a low-threshold Internet platform for the independent and structured introduction of industry 4.0 in SMEs. The research project enables a goal-oriented introduction and implementation of Industry 4.0 and thus contributes to ensuring the sustainable competitiveness of companies.Year: 2018Funding: NBankDuration: 03.05.2018 - 30.04.2020

![]()

![]()

-

InterKom - Communication design in interorganizational production networksThe aim of the research project is to develop a standardized method for the quantitative analysis and design of communication interfaces in interorganizational production networks. The method should enable the identification of weak points in communication networks and subsequently the improvement communication flows by means of appropriate measures.Year: 2018Funding: DFGDuration: 2017-2020

![]()

![]()

-

QuantiLoPe - Quantitative analysis and evaluation of the causes of low logistical performance along the company's internal supply chainThe aim of the research project is to develop a procedural model for the quantitative analysis and evaluation of the causes of low logistical performance along the company's internal supply chain. The development of end-to-end, multi-stage symptom-cause-relationships forms the basis for a transparent presentation of the basic logistical interrelationships, which should enable SMEs in particular to independently derive effective improvement measures and to sustainably increase their logistics performance.Year: 2018Funding: BVL, AiF, IGF, BMWiDuration: 01.12.2016 - 31.12.2018

![]()

![]()

-

WorkCam - Real-time, camera-based ergonomics assessment and action derivation in assemblyThe aim of the research project "Real-time capable and camera-based ergonomics evaluation and action derivation in assembly (WorkCam)" is the automated, contactless or camera-based motion detection, analysis and evaluation of employees at their workplaces by means of a 3D measuring technique to be developed. It is also intended to derive recommendations for the improvement of ergonomic movement sequences under real conditions on the basis of the evaluation result.Year: 2017Funding: BMWi | IGF | AiF | GVBDuration: 2017 - 2019

![]()

![]()

-

MoKon - Model-based configuration of projects to restructure production and assembly areasAs part of the research project, a model is to be developed that will enable small and medium-sized enterprises (SMEs) to independently and efficiently configure projects to restructure their manufacturing and assembly areas. The methodological support will enable SMEs to set up a target-oriented project programme which is structured in terms of content, organisation and timing and which takes into account all elements of restructuring.Year: 2017Funding: GVB, AiF, IGF, BMWiDuration: 2017 - 2018

![]()

![]()

-

SafeMateThe aim of the research project SafeMate is to implement collaborative assembly systems in cross-industry applications and to develop general strategies and concepts for the introduction and design of such systems. These general strategies are to be summarised in a guideline, which is intended to provide companies with guidance in the form of action and decision-making corridors when designing collaborative assembly systems.Year: 2017Funding: BMBFDuration: 01.01.2017 - 31.12.2019

![]()

![]()

-

MiWEB - Identification of employee-specific training needs and conceptual design of technical training measuresThe aim of the research project is to develop a multi-stage, dialogue-based methodology that enables companies to identify employee-specific training needs in a systematic and low-cost manner. On this basis, a procedure is being developed which enables the conception of new types of further training measures taking into account employee and company-specific basic conditions using automation technology as an example.Year: 2016Funding: ESF | NBank | Region HannoverDuration: 2016 - 2017

![]()

![]()

-

KomPEP - Competent-oriented personnel planning in the production of manufacturing SMEs using MESThe aim of personnel planning is to secure the competitiveness of a company in the long term by providing employees with qualifications that meet their requirements. Production planning, on the other hand, makes use of the available resources at short notice in order to reduce production costs and times, among other things, and to increase quality. The separate analysis at company and production level often leads to a conflict between the long-term orientation of personnel development and the short-term striving for productivity gains in production. The aim of the project is to transform the knowledge gained so far into an integrated technology and competence-oriented planning approach into an industrial application scenario. To this end, it is necessary to extend the previous planning approach to include the consideration of methodological, social and personal competencies, forms of group work and further training measures into a competence-oriented production and personnel planning methodology. Furthermore, the integration of this production and personnel planning methodology into an MES for industrial application in SMEs is planned.Year: 2016Funding: DFGDuration: 2016 - 2018

![]()

![]()

-

INTRO 4.0 - Capability and implementation strategies for industry 4.0In order to promote the integration of Industry 4.0 in companies, the INTRO 4.0 project aims to develop strategies for enabling and introducing Industry 4.0, especially in cooperation with SMEs. The core elements of the project include requirements assessment with the project partners, the development of industry 4.0 methods, the risk and potential assessment of the developed methods and finally the creation of a guideline for the introduction of industry 4.0 The guideline is intended to provide solutions for the implementation of industry 4.0 methods and technologies depending on the maturity of the companies. INTRO 4.0 places a special emphasis on the integration of people by focusing on the competence development of its employees.Year: 2016Funding: BMBFDuration: 01.2016-12.2018

![]()

![]()

-

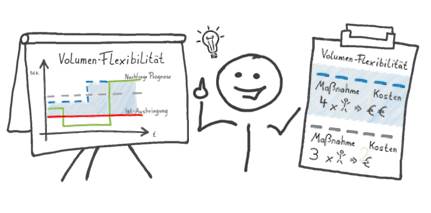

GeProMe - Decision support for manufacturing SMEs to optimize the production system in case of fluctuating demand quantitiesThe dynamism of the markets results in fluctuations in demand volumes. SMEs are increasingly having to react to this trend by adapting their output quantities in a flexible manner.Year: 2016Funding: BVL, AiF, IGF, BMWiDuration: 2016 - 2018

![]()

![]()

-

HaLiMo - Integrative logistics model for linking planning and control tasks with logistical targets and control parameters of the internal supply chainThe aim of the research project is to develop an integrative logistics model for the interdependencies between generally defined planning and control tasks and the logistical targets in the core processes of an internal supply chain.Year: 2015Funding: DFGDuration: 2014-2017

![]()

![]()

-

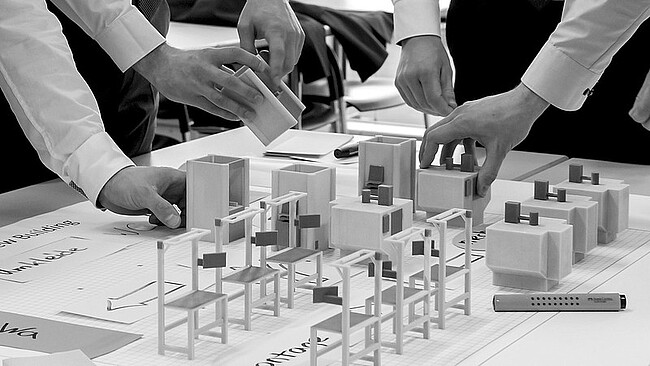

ReFa - Model-based restructuring of factoriesThe factory structure forms the backbone of the factory and is therefore one of the central results of a factory planning process. In particular, the trend towards shortening planning cycles and the resulting increase in factory planning projects make it necessary to be able to quickly and purposefully identify the right measures for factory restructuring...Year: 2015Funding: DFGDuration: 2014 - 2015

-

DynaKom - Modelling and design of dynamic business and communication processes in the factoryThe increasing dynamism of the production environment means that factories are subject to permanent changes. Against this background, it is a central challenge of factory planning to continuously adapt factories to the requirements of the dynamic environment. The corresponding adaptation of communication structures is increasingly becoming a success factor. Since there are no methods for the systematic planning of plant-specific communication structures in a dynamic company environment, the project develops a model and a method for the description and design of dynamic business and communication processes in the factory. Based on an analysis of the forms of change in the factory, factory-specific reference profiles for communication structures are determined and ways are described how these can be implemented.Year: 2014Funding: DFGDuration: 2012 - 2014

![]()

![]()

-

prokoMA - Process and competence oriented method selection in manufacturing SMEsIncreasing competitive pressure is forcing companies to continually improve their processes. There is currently no focus on parallel process improvement and competence development. The aim of this research project is to develop a systematic approach to the efficient selection of methods for process improvement and at the same time to increase employee skills. The results will be converted into a practical software tool, which will be made available free of charge on the IFA homepage after completion of the project.Year: 2014Funding: GVB, AiF, BMWiDuration: 2014 – 2016

![]()

![]()

-

ProWandel - Planning process of the socio-technical adaptability in factoriesDevelopment of a process model that allows the integration of employee competencies as well as work and company organization into the planning of a factory's adaptability.Year: 2014Funding: DFGDuration: 2012 - 2014

-

Development of a methodology for the dynamic, future-oriented disposition of inventoriesThe analysis of strengths and weaknesses of existing approaches to the dimensioning of safety stocks serves to develop a methodology for the dynamic, future-oriented disposition of stocks.Year: 2013Funding: DFGDuration: 2010-2013

![]()

![]()

-

SFB 653 - N3: Component-status-driven maintenanceEven a nasty piece of metal can be smart. If it contains all the information for further processing. If it is a "intelligent" component....Year: 2013Funding: DFGDuration: 2013 - 2017

![]()

![]()

-

WiTa - Effective model for deadline deviationWithin the scope of the research project, a quantitative effect model for calculating adherence to deadlines in industrial manufacturing processes is being developed.Year: 2013Funding: DFG - Deutsche ForschungsgemeinschaftDuration: 11/2013 - 08/2016

![]()

![]()

-

ProLoPoly - cybernetic simulation game for the mediation of interdepartmental logistic connections in SMEsThe aim of this research project is to develop a cybernetic simulation game for employee qualification in SMEs. The simulation game is to be used to demonstrate interdependencies in SMEs and to generate a logistics-oriented and cross-functional employee thinking.Year: 2013Funding: AiFDuration: 2013-2015

-

Development of a model for planning and controlling operation centresIn cooperation with the Institute for Standardized and Applied Hospital Management (ISAK) a general model for more efficient planning and control of operation centres (OP centres) in hospitals is being developed within this research project.Year: 2013Funding: DFGDuration: 08/2013 - 07/2016

-

Development of a model-based methodology for potential evaluation in distribution logisticsThe design of distribution logistics significantly influences the logistics costs and the logistical performance of a company. It is therefore an essential lever for improving competitiveness. The potential fields and measures to improve distribution logistics are diverse and interdependent. The aim of the research project is to develop a model-based methodology for strategic evaluation and potential analysis of distribution logistics.Year: 2013Funding: DFGDuration: 2013-2016

-

VReP - Improving resource efficiency in production operationsLow consumption and high availability of production resources represent a major competitive factor for manufacturing companies in Germany. Material and energy costs thus account for a large part of the total costs. The aim of the project is to develop a procedure for the systematic introduction and anchoring of measures to improve resource efficiency in ongoing production operations.Year: 2013Funding: PtJ und BMBFDuration: 2013-2015

![]()

![]()

-

RampUp Qualification: Simulation game to qualify SMEs for launching new productsThe aim of the research project is to develop a tool for qualifying employees of SMEs for future start-up situations.Year: 2013Funding: BVLDuration: 2013-2015

![]()

![]()

-

StöGröM - Sustainable disturbance management in manufacturing SMEsThe aim of the research project is to develop a systematic approach that shows SMEs a methodological procedure for the sustainable implementation of preventive and reactive disturbance management.Year: 2013Funding: BVI, AiF, IGF, BMWIDuration: 2013 - 2014

![]()

![]()

-

SFB 489 - Evaluation of measures in productionBased on the SFB489, a generally applicable model for the monetary and logistical evaluation of measures in production is being developed in cooperation with Siemens AG in this research project "Evaluation of measures in production".Year: 2013Funding: DFGDuration: 2011 - 2013

![]()

![]()

-

Sustainable Factories - Assessment and design of sustainable, resource-efficient factoriesThe aim of the project is to develop a method for the holistic planning, design and evaluation of energy-efficient factories.Year: 2012Funding: BMBFDuration: 07/2010 - 03/2012

-

Development of a model-based methodology for logistic and monetary evaluation and procurement designThe aim of the research project is to develop a model-based methodology for the logistic and monetary evaluation and design of procurement. With the help of this methodology, companies are enabled to analyse their procurement processes in a short period of time, to identify potentials and to derive measures to increase them.Year: 2012Funding: DFGDuration: Mitte 2012

-

Development of a model-based, logistical controlling approach for supply and assembly areasAn approach is being developed to systematise the time-dynamic description of all assembly processes with regard to the relevant logistical and monetary parameters.Year: 2012Funding: DFGDuration: 2010 - 2012

![]()

![]()

-

Design and evaluation of structure variants (GBS)The aim of the research project is to develop a methodology that enables the systematic design and evaluation of structural variants in factory planning projects.Year: 2011Funding: DFGDuration: 2010 - 2011

-

Future-proof and target-oriented factory planning to support process and product quality (Q²FaP)Within the scope of the project, it will be determined how the goal of high process and product quality can be taken into account during factory planning.Year: 2011Funding: DFGDuration: 2010 - 2012

![]()

![]()

-

WaProTek - Convertible process architecturesIn the future, companies will be able to identify acute systemic needs for the transformation of their production systems in the areas of organization, human resources, logistics and technology, to design economic solutions and to operate them in a qualified manner.Year: 2011Funding: BMBFDuration: 2010 - 2013

![]()

![]()

-

TecKompASS - Integrated technology and competence oriented work planning in socio-technical systemsDevelopment of a new type of work planning methodology with the aim of integrating employee competence as a qualitative feature in the work planning process.Year: 2011Funding: DFGDuration: 2012 - 2013

![]()

![]()

-

FTP-Roadmapping - Integrative factory, technology and product roadmapping based on a holistic influence and evaluation modelIntegrative roadmapping based on a holistic influence and evaluation modelYear: 2010Duration: Bis 2010

-

SFB 871 - Modelling Regeneration Supply ChainsThere are no machines and equipment in the supermarket. And because capital goods are usually still expensive, it is worthwhile to take a close look at the repair work....Year: 2010Funding: DFGDuration: 01/2018 - 06/2022

-

alpha-factor - Mathematical description and evaluation of the influence of capacity flexibility and load distribution on logistical system behaviorThe aim of this research project is to mathematically describe the hitherto unquantifiable influence of capacity flexibility and load distribution on logistical system behavior on the basis of the theory of logistical characteristic curves. To this end, the stretch factor? 1 of the characteristic line theory, which until now could only be determined empirically and which - as shown in preliminary studies - depends on the available capacity flexibility and the distribution of the load, is to be converted into elementary parameter proportions.Year: 2010Funding: DFGDuration: Bis 2013

-

RampAble - Design of ramp-up capable production systemsManufacturing companies are currently faced with the challenge of having to integrate an increasing number of products into their production systems in ever shorter periods of time. The RampAble research project is therefore developing a methodology that enables companies to record and evaluate the start-up capacity of their production system and to increase it in a targeted manner by means of suitable measures.Year: 2010Funding: BVI, AiF, BmWiDuration: Voraussichtlicher Abschluss 12/2012

-

KomFaP - Design and evaluation of communication-oriented factory processes at the interfaces of operational work processesCommunication is invisible and nonetheless an important control variable in logistical planning - and is therefore the subject of this project.Year: 2009Duration: Bis 2009

-

ProdLog-Design - Maturity-based development paths for performance-enhancing design of production logistics in small and medium-sized companiesDevelopment of a methodology for the systematic design and evaluation of structural variants in factory planning projects.Year: 2009Duration: Bis 2009

-

Lean ChangeabilitySlim, versatile factories for small and medium-sized businessesYear: 2008Duration: Bis 2008

-

Pro-LEANSustainable and increase the capacity and utilization of production plants.Year: 2008Duration: Bis 2008

-

koLasCombined laser processing with adaptive gripping technologyYear: 2007Duration: Bis 2007

-

SynFAP - Synergetic factory planning based on an integrated process and space modelThe project on synergetic factory planning is intended to meet the demand for a new approach to cooperative and integrative planning. Synergy refers to the positive effect of cooperation on a coordinated overall performance. The project focuses on cooperation between factory planning and architecture.Year: 2006Funding: Stiftung IndustrieforschungDuration: 2004 – 2006

-

GVP - Global Variants Production SystemStrengthening Germany as a business location - and growing internationallyYear: 2005Duration: Bis 2005

-

iAero – Development of a Self-Learning, Automatic Parameterization of the Aerodynamic OrientationIn the light of rapidly changing markets constantly increasing requirements are imposed on production- and assembly processes regarding flexibility and variant diversity. In recent years strong efforts have been made to improve flexibility of the value-added process itself. The aim of this research project is to develop a method enabling the independent and continuous determination of parameter settings for aerodynamic orientation. The existing System is to be empowered to autonomously adjust parameter settings to new components and changing external conditions. The intention is to decrease efforts and specialized knowledge required for parameterization. The system control needs to be able to configure parameters automatically to attain the desired quality of orientation. In addition, the system must be able to react dynamically to changing external conditions and interferences in order to maintain a sufficient quality level within the ongoing process. An optimization algorithm will be developed for both the identification of optimal parameter settings as well as their dynamic adaption. The algorithm should initially be tested and if applicable modified in an operational simulation environment. Subsequently the algorithm should be implemented into the control structure of a real system.Funding: DFG - Deutsche ForschungsgemeinschaftDuration: 2014 - 2016

![]()

![]()